Company News, 09-28-2018

Laser marking is a marking method that uses a high-energy-density laser to locally irradiate the workpiece to vaporize or change the color of the surface material, thereby leaving a permanent mark.

As a modern precision machining method, laser marking technology has unparalleled advantages compared with traditional machining methods such as corrosion, electrical discharge machining, mechanical scribing, and printing:

1. The laser is used as the processing method, and there is no processing force between the workpiece and the workpiece. It has the advantages of no contact, no cutting force, and little thermal influence, which ensures the original accuracy of the workpiece. At the same time, it has wide adaptability to materials, and can make very fine marks on the surface of various materials with very good durability;

2. The spatial controllability and time controllability of the laser are very good, and the material, shape, size and processing environment of the processing object have great freedom, especially suitable for automatic processing and special surface processing. And the processing method is flexible, which can not only meet the needs of laboratory-style single-item design, but also meet the requirements of industrial mass production;

3. The laser marking is fine, and the lines can reach the order of millimeters to microns. It is very difficult to imitate and change the marks made by laser marking technology, which is extremely important for product anti-counterfeiting;

4. The combination of laser processing system and computer numerical control technology can form efficient automatic processing equipment, which can print various characters, symbols and patterns, easy to use software to design marking patterns, change marking content, and adapt to the requirements of modern production with high efficiency and fast pace ;

5. Compared with traditional screen printing, laser processing has no pollution source and is a clean and pollution-free high-environmental processing technology;

Laser marking technology has been widely used in all walks of life, opening up broad prospects for high-quality, high-efficiency, pollution-free and low-cost modern processing and production. With the continuous expansion of the application field of modern laser marking, the requirements for the miniaturization, high efficiency and integration of the laser manufacturing equipment system are getting higher and higher. big push.

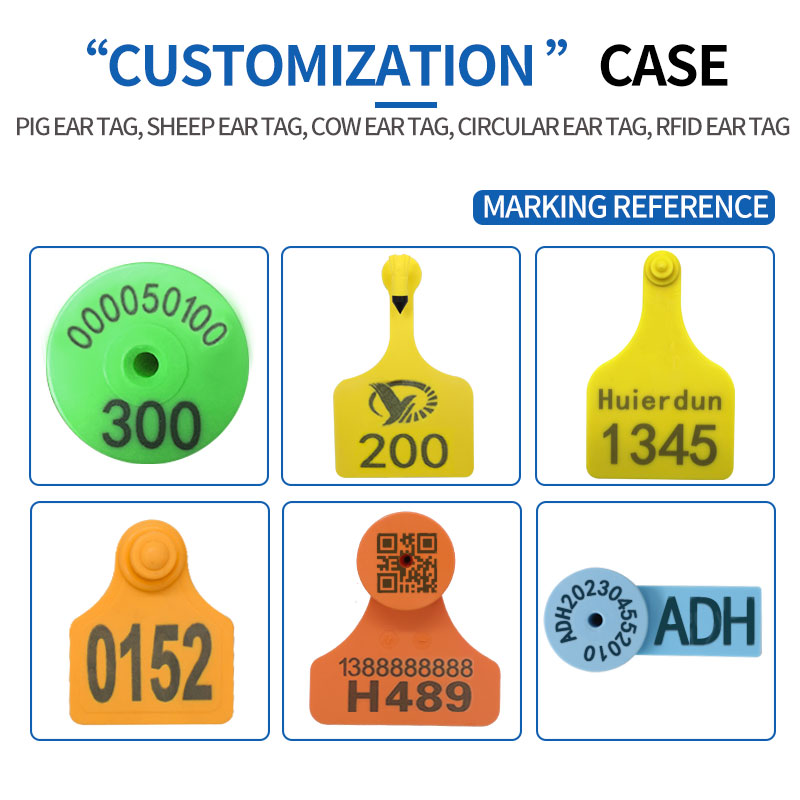

1.One-piece animal ear tag Single piece unique design, low drop rate. Self

Learn more >Huier Shield (Shandong) Intelligent Technology Co., Ltd.

+86 18254177625 (Nonworking Time)

Email Address: sale@heshield.com

Copyright: Huier Shield (Shandong) Intelligent Technology Co., Ltd. All rights reserved.

Key Word: Ear Tag Bolt Seal Plastic Seal Cable Seal Meter Seal Plastic Padlock Metal Strap Seal